DIGITAL TWIN SOLUTIONS IN ANGOLA

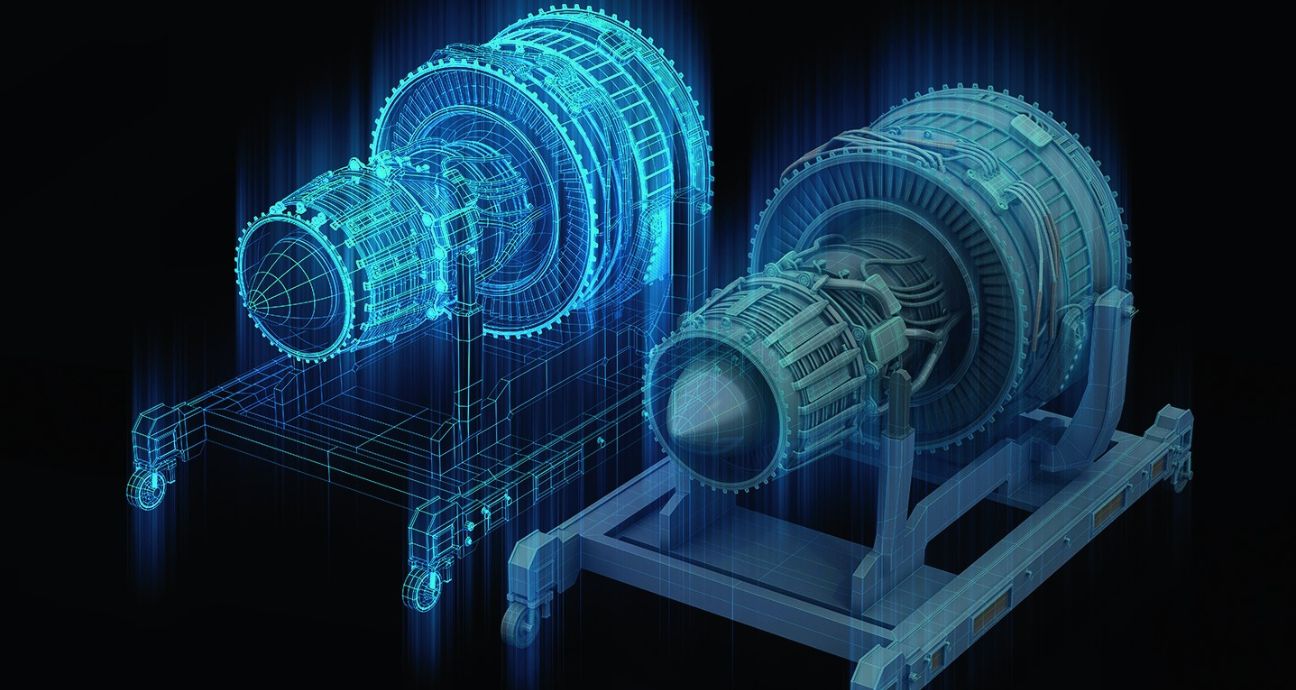

For digital transformation and data management services related to oil and gas, EIWAA Oil and Gas Services is your digital twinning solution partner in Angola. We do this by providing virtual replica models of oil and gas assets in Luanda and Soyo. For digital twins of ships, vessels, and yachts, as well as for oil and gas digitalization and real-time asset monitoring, EIWAA is the leading provider of digital twin solutions in Angolan ports. The services offered by EIWAA Digital Twin Services in Angola include oil and gas digitization, scan to model, and scan to visualization. LiDAR scan data is used in detailed engineering to visualize the onboard pipe system and as-built information. FARO laser scanners are used to generate As-Built drawings, precise and seamless documentation, and other documents.

The first step in retrofitting or converting a ballast water treatment system (BWTS) installation as part of a feasibility assessment is to use LiDAR scanning services. Before the ship or vessel is retrofitted and installed, the “as-built” characteristics are captured using 3D scanning services and modeling of the ballast water treatment system (BWTS) installation. Feasibility studies, point cloud refining, point cloud isolation, 3D modeling services, engineering, and scanning plan formulation are all included in laser scanning solutions for yachts, ships, and boats.

DIGITAL TWINNING OF SHIPS AND VESSELS

Because ship, vessel, and FPSO design is such a complex process, it demands accuracy and innovation. By providing naval engineers and architects with a powerful tool to enhance collaboration, optimize designs, and expedite processes, digital twin technologies revolutionize ship design services. Naval architects and engineers can test different scenarios and assess the effects of design changes before they are actually implemented thanks to the virtual replica’s extensive simulations. This function not only speeds up the design mode but also significantly reduces the possibility of errors and expensive modifications during the shipbuilding phase. Shipbuilders may view the entire vessel, from the hull structure to the onboard systems, ensuring that every component functions as together for optimum performance and efficiency. Maritime digital twin technology, which provides real-time insights into operational parameters, can be used to optimize ship performance. Ship operators can make informed decisions that enhance overall performance, including fuel consumption and engine efficiency, by employing these virtual replica models. Quick adjustments and revisions are made possible by real-time monitoring, ensuring that the vessel operates as effectively as possible and complies with environmental regulations. In the past, ship maintenance and repair has been a challenging and time-consuming process that usually requires removing ships from service for inspections and repairs.

Ship Building

Ports

Ships, Vessels and Yachts

Digital Implementation

Digitalization

Digital Twinning

DIGITAL TWIN SERVICES IN ANGOLA PORTS

By creating a digital replicate of the facility, all port facilities may be viewed and managed and It can be used to reduce risks, increase safety, lessen accidents, and coordinate during emergencies like catastrophes and accidents. As a result, port operations are more efficient and sustainable. You may view real-time data about your port facility with your digital twin model, providing you with immediate access to information about the condition of your systems. Digital twins and their replica model are revolutionizing port operations. By speeding up and improving construction project coordination, streamlining daily operations, and reducing energy consumption, these digital twin technologies are establishing the foundation for smarter, greener, and more efficient ports. To fully profit from digital twins, marine ports must, however, get over challenges like data integration and ensure that their staff is ready for the future.

DIGITAL TWIN IMPLEMENTATION PARTNER IN ANGOLA

By offering digital replicas or 3D models, EIWAA is one of the top maritime 3D laser scanning companies in Angola for digital twin solutions and digital implementation for shipbuilding, ports, ships, vessels, and yachts. In marine surveys, 3D imaging and 3D rendering are non-contact and non-destructive testing technologies that digitally record and produce point clouds.

- 3D Imaging

- Reality Capture

- 3D Modelling

- Boat and Yacht 3D Measurement

- Digital Twining of Vessels, Ships and Yachts

FREQUENTLY ASKED QUESTIONS

The use of laser scanning and 3D Modelling Service in the shipbuilding industry is a technology that aids shipyards in completing projects more quickly, effectively, and safely.

Real-time data or As built data can be captured by 3D laser scanning instrument. As-built survey, reality capture, and existing conditions survey are examples of frequent uses in offshore rigs and vessel retrofitting. Sequencing, scheduling, and simulations for construction are the steps for Reverse Engineering and retrofitting solutions.

To accomplish best practices for boat maintenance, new building, and (BWTS) Ballast Water Treatment Systems retrofit, Hull air lubrication system retrofitting engineering; we are specialist in quickly and precisely recording current conditions utilizing the most advanced, well-proven technology in laser scanning and precision elevation. We worked with naval businesses and industry experts to provide shipping firms with high-quality services at all Major ports.

When completing ship checks, it is customary to have designers and/or engineers on board, where they measure the current systems and areas with tape measures. The scope and construction papers are then developed using these measurements. To account for differences between the measurements and reality, allowances must be made due to the measurement uncertainty.