OFFSHORE 3D LASER SCANNING IN QATAR

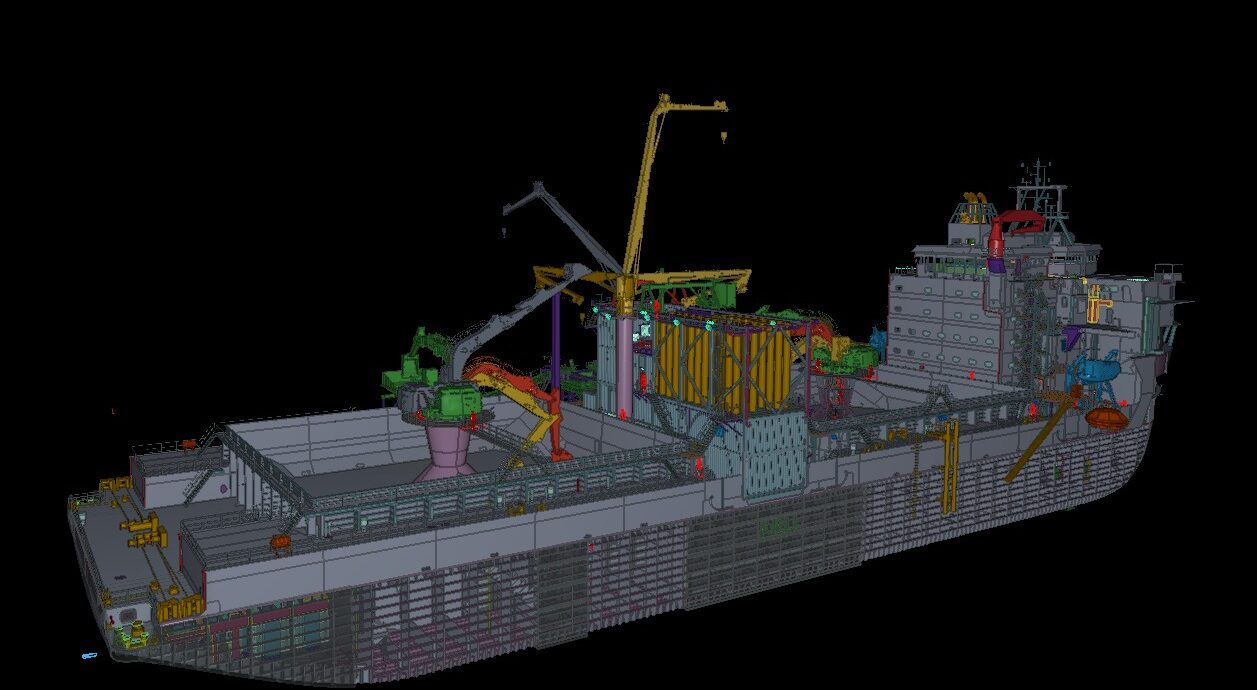

Our marine 3D laser scanning services in Qatar offer precise as-built drawings, as-built documentation, laser dimensional measurement, alignment, and digital twin models of boats, yachts, ships, vessels, and offshore rigs. High-precision laser scanners record every part of your ship, including the hull, piping system, engine rooms, etc. We provide maritime digital transformation services in all of Qatar’s major ports and offshore for 3D laser scanning, yacht 3D scanning, digital twin in shipbuilding, offshore platform 3D laser scanning, hull 3D scanning, line plan preparation, and scan-to-CAD for ship design.

In compliance with Lloyd’s Register, ABS, BV, and DNV ship classification criteria, 3D laser scanning can be used to digitally twin boats, yachts, ships, vessels, and offshore rigs. Vessel geometry can use 3D scanning to provide three views of the body plan (bow to stern), profile plan (sheer plan showing keel, deck, stem, and stern), and half-breadth plan (waterline and hull curvature). Our marine digitization and 3D scanning services include, but are not limited to,

- Dry docking survey: recording the ship's hull in three dimensions both before and after maintenance and repairs.

- As-built documentation: Actual information and exact measurements of ship structures, ballast tanks, pipes, and engine rooms are documented for future reference.

- Retrofit and conversion: ballast water treatment system retrofitting, LNG conversions, ECGS scrubbers, and lodging improvements.

- Design and engineering: creating accurate Scan-to-CAD or Scan-to-BIM models related to ship models, hull design, and design.

- The production of a digital twin, a virtual model that can be used to track and replicate prototypes.

- Hull Damage Assessment: 3D mapping of damaged regions (dents, structural deformation, etc.).

- Thickness assessments and 3D measurements for hull repair identify bending or distortion in order to plan a hull repair.

- Equipment and engine upgrades: Explains how new equipment with clash detection is installed.

- 3D designers renovate yachts' and ships' interiors. Hull form development is a preliminary draft made with naval architecture software such as Maxsurf, Rhino Marine, and Auto Ship.

- Pipe rerouting and replacement: Identify the specific pipes and their accessible locations.

Marine 3D Laser scanning

Digital twin

Hull Damage assessment

Hull Lines plan Preparation

Scan-to-CAD

Retrofit solutions

HULL LINES PLAN

Using a 3D scan, our naval design develops tugboat line plans to enhance hull stability, efficiency, retrofit, extension, or damage repair. CFD analysis and 3D modeling are used in digital modeling for transforming line designs. Preparing a line plan involves gathering data, developing a hull form, drawing three views of the sheer/profile plan, half breadth plan, body plan, line fairing, and the final output hull plan. EIWAA develops hydrostatic hull line designs, stability books, and construction drawings.

- Welding Theory Session

- Welding Training

- IRS/BV/ABS Approved Welding procedure.

- Welding Foreman Assistance

- Qualified Welding position of 1G, 2G, 3G,4G,5G & 6G

- AWS/ASME Approved Welders