Storage Tank Inspection

Storage tanks are an asset that deserves attention. These tanks can be fabricated of metal, either field erected or shop fabricated, or non-metallic materials, such as polyethylene or fiberglass-reinforced plastic (FRP). They can be used to store petroleum products, chemicals, or waste materials. The field of storage-tank inspections comprises both in- and out-of-service inspections of vertical and horizontal storage tanks, both above and below ground. A combination of techniques is used to provide a comprehensive condition report on the overall tank floor, shell, roof and structure, including engineering calculations in accordance with API 653 & 650 and other relevant specifications.

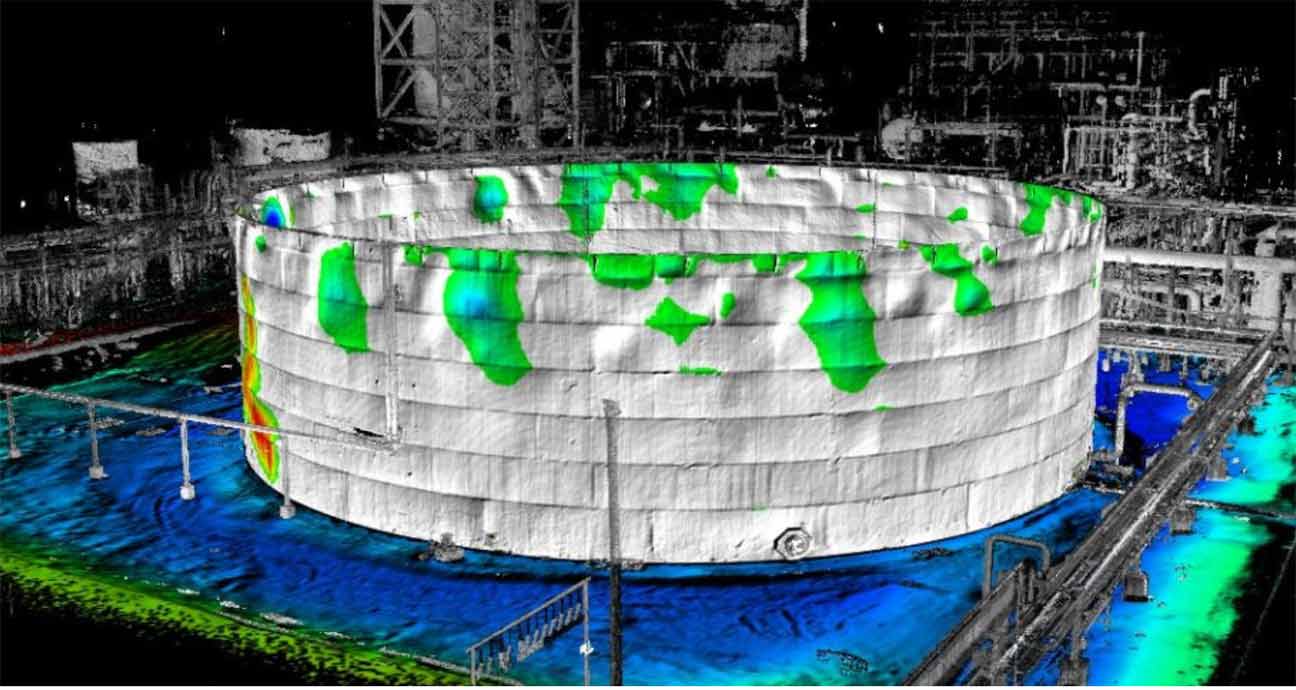

EIWAA specialized in analyzing service conditions of storage tanks by advanced laser solutions and techniques to conducts the dimensional survey & settlement analysis of storage tanks as per the API 653 Standards. Real time scanned images of storage tanks will help the maintenance/major repair/alternations of storage tanks as per the API 653/650 Standards.

Storage tank Dimensional Survey

Storage tank dimensional service can be performed by laser measurement service. Storage tank dimensional survey includes storage tank verticality check, Tank straightness measurement, Storage tank roundness survey, Fuel tank dimensions, Fuel oil tank dimensions chart, Storage tank verticality, Measurements of Roundness, Plumpness and Roundness of storage tank, Storage tank Deformation, Storage tank dimension etc.

- Tank Peaking/Banding Survey

- Tank Alignment Survey

- Laser Measurement

- Tank ovality,Roundness,Verticality

Tank Dimensional Survey

API 650 tank Inspection

Tank settlement Survey

Storage tank Settlement Survey & NDT Inspection

Storage tank settlement survey covers the scope of foundation settlement survey, storage tank tiltness, storage tank verticality measurement etc. Storage tank settlement survey shall be performed by advanced total station survey and evaluation reporting shall be by tank settlement software’s. Approved Fuel tank NDT Testing methods for oil tank bottom plate as per API 653 Inspection are MFL Tank floor Inspection. Normally MFL Tank floor inspection are performed for both tank bottom plate as well as annular plate of storage tank including the critical zone.

- In Service Inspection

- Tank Shell Thickness Evaluation

- Vacuum Box Test

- Tank Leak Test

- Remaining life Assessment

- Fit to Use Inspection and certification

Our storage tank inspection services covers the scope of Non-destructive Inspection Services like Vacuum Box Testing Inspection, Leak Testing Services, Corrosion Survey, API 653 Tank Inspection, Tank dimensional service, Storage tank Dimensional Services by laser measurement services. Storage tank dimensional Services in UAE covers storage tank verticality checking, Storage tank verticality survey services, Tank Alignment Survey, Storage tank peaking/banding survey etc.

Storage tank inspection services as per API 653 Standard, associated with the requirements of piping and pipeline inspection services in tank terminals. Safe fill height calculation of storage tanks can be determined by our 3D laser scanning and laser measurement services as per API Standards. Above Ground Storage tank volume calculation or Storage tank calibration shall be determined by advanced 3D Scanning Services and remote sensing method. In Storage tank NDT Testing, Storage tank floor inspection have major role to find out the corrosion assessment of storage tank bottom plate and floor.

Frequently Asked Questions

If you prefer the best oil tank testing company, it is always EIWAA Inspection Testing services for storage tank inspection testing and certification. Advanced 3D MFL Tank floor inspection are 3D MFL floor Tank inspection and customer can assess the complete 3D image of MFL tank floor mapping conditions.

Storage tank peaking and banding measurement can be performed by API 653 Inspector with the help of 3D scanner with wide range of measurements which covers the total height of storage tank. Peaking and banding inspection report includes the tank peaking and banding details, tank verticality measurements, storage tank ovality and roundness survey details, storage tank dimensional details etc.

Petroleum storage tank fitness for service assessment means the certification of storage tank states that tank is fit for use for inward/outward operations. Fitness for service evaluation and Fitness for service (FFS) assessment depends upon the structural integrity of storage tank. Remaining life assessment is based on the condition assessment result of storage tank which is evaluated by the API 653 Inspector and the remaining is calculated based on the NDT Test result. Remaining life assessment and RLI assessment is the approved document up to the next valid date of storage tank inspection requirements.

As per the approved storage tank inspection test, API 650 Inspector will review the extend of NDT examination as well as approved storage tank inspection procedure. API 653 conduct the inspection with reference to the storage tank inspection checklist. Extend of NDT Examination and acceptance criteria described in storage tank inspection procedure and inspection checklist. Storage tank inspection acceptance is absolutely based on the discretion of inspection engineer. Fitness for service evaluation is issued based on the condition assessment of storage tank and next inspection frequency is also depends upon the API 653 condition assessment.