Above Ground Storage tank Calibration:

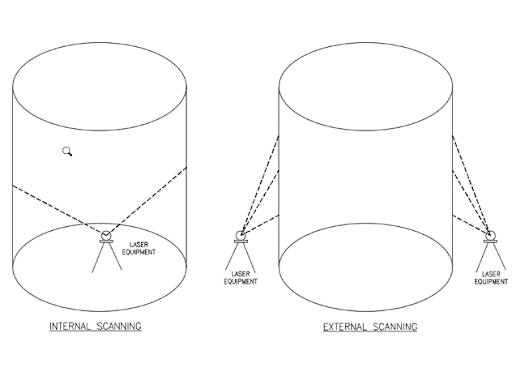

Above Ground Storage tank calibration is performing as per API Manual of Petroleum measurement Standards Chapter 2 Section 2D(API 2.2D). This online calibration is commonly known as EODR calibration (Electro Optical Distance Ranging) working under the principle of LiDAR (Light Detection and Ranging). This is an advanced method of online calibration by advanced Total Station. Laser source detects objects and it create x,y,z coordinates by 3D Laser Scanning equipment and it capture all the objects within the limit of 120mtr at 360 degree; is also called 3D Laser calibration technology.

Pre-Assessment of fuel oil tank Calibration:

Preliminary assessment shall be carried out by calibration Engineer and ensure the site conditions are,

- All the major Repair/alternation works related to the tank fabrication have been completed.

- All the Non-Destructive Testing and Hydro tests have been performed in accordance with the API 650 and API 653 Standards.

- The storage tank should be completed with internal cleaning works, dried and absence of scaffoldings.

Fuel tank Calibration Procedure:

Tank Calibration or Tank strapping is the science of determining the exact true volume of a storage tank. It is for obtaining accurate measurements of quantity or tank volume.

Fuel oil Tank Terminologies:

Datum Plate: Plate located along the vertical axis descending from the dipping reference point where taking dip measurements.

Dip Hatch: Tank top opening through which dipping, ullaging or sampling operations were carried out.

Dip Pipe: A hollow metal pipe fitted below the dip hatch directly above the datum point and acts as a guide for the dip weight. Dip pipe is compulsory for a floating roof tank.

Shell Plate Thickness: This is the value of thicknesses in mm at each course obtained from ultrasonic thickness measurement (UTM).

Tank Height: This is the vertical distance between the datum and dipping reference point.

Dip: It is vertical distance between the datum reference point and the tank product level.

Course: Circumferential ring of plates in every storage tank.

Deadwood: It is called ‘positive’ when the volume of the fitting adds to the effective capacity of the tank, or ‘negative’ when the capacity volume of the fitting subtracts from the effective volume..

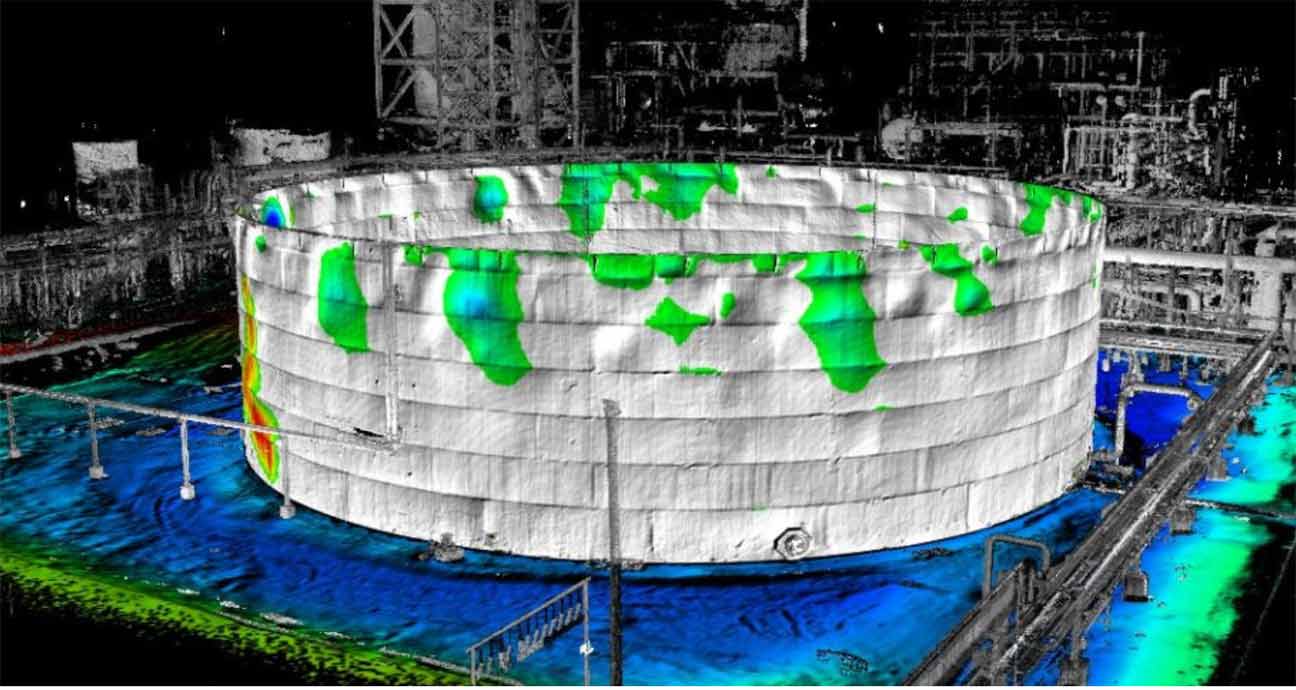

EODR Online Calibration Method: Storage Tank Calibration Solution introduces an advanced laser Scanner. This advanced LiDAR 3D laser scanner is placed directly inside the storage tank. 3D scanner with advanced software allow producing 2D and 3D deliverables for accurate calibration result.

Storage Tank Calibration Solution introduces an advanced laser Scanner. This advanced LiDAR 3D laser scanner is placed directly inside the storage tank. 3D scanner with advanced software allow producing 2D and 3D deliverables for accurate calibration result.

Storage tank Calibration chart comprises,

- Plate thickness at each course

- Height

- Safe filling height

- Elevation or height

- Tiltness of tank

- Dimension s of all appurtenances

- Density and temperature of product

- Floating roof height